Acoustic panels are widely used as decorative materials and are often cut or carved into various shapes for both aesthetic appeal and soundproofing purposes. These panels are then assembled into walls or ceilings. Common processing methods for acoustic panels include punching, slotting, and cutting. However, traditional manual cutting often leads to uneven parameters, burrs, and lower efficiency.

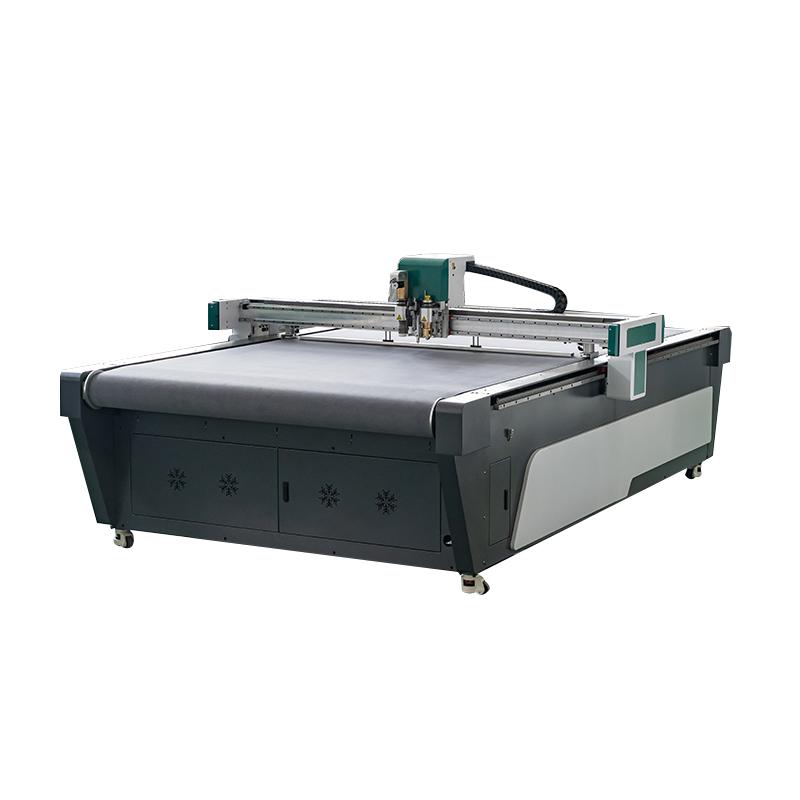

With the increasing demand for precision in acoustic panel processing, traditional cutting methods for polyester fiber sound-absorbing panels can no longer meet the required standards. This is where the Digital CNC Cutting Machine for polyester fiber sound-absorbing panels comes in, providing an efficient and precise solution for cutting.

Key Advantages of the Vibration Knife Cutting Machine:

High Precision Cutting

The vibration knife cutting machine uses high-frequency vibration to cut edges that are neat and burr-free. Compared to manual cutting, it can simultaneously perform three processes: slotting, punching, and cutting. This results in faster cutting speeds and higher precision, reducing material wastage and improving overall product quality.

Advanced Software & Automatic Error Compensation

The machine features super layout software that has been tested by numerous manufacturers. This software helps save over 10% of materials by optimizing the layout of the cuts. Additionally, the automatic error compensation system ensures that cutting errors are controlled within ± 0.01mm, maintaining high accuracy throughout production.

Increased Efficiency

The vibration knife cutting machine dramatically improves production efficiency. The cutting process is significantly faster than manual methods, and with its ability to handle multiple processes simultaneously, it greatly shortens production cycles.

Customizable Cutting Capabilities

The machine is highly adaptable, supporting different cutting materials and thicknesses. It can handle materials up to 50mm thick, and the large cutting size of 2500mm x 1600mm accommodates various project sizes.

Technical Parameters:

Machine Type: YC-1625L Fixed Platform

Multi-functional Machine Head: Replaceable design for various cutting tool configurations

Tool Configuration: Includes multiple cutting tools, indentation wheels, and signature pens

Safety Features: Infrared induction for quick and reliable safety response

Cutting Speed: 80-1200mm/s

Translation Speed: 800-1500mm/s

Cutting Thickness: ≤ 50mm (customizable)

Material Fixation: Intelligent multi-zone vacuum adsorption

Servo Resolution: ≤ 0.01mm

Transmission Method: Ethernet port

Control Panel: Multi-language LCD Touch Screen

Power Supply: 9.5KW rated power, 380V ± 10%

Dimensions: 3400mm x 2300mm x 1350mm

Large Cutting Size: 2500mm x 1600mm

Large Discharge Width: 1650mm

Summary

The Digital CNC Cutting Machine for polyester fiber sound-absorbing panels provides an efficient, precise, and customizable solution for the production of acoustic panels. With its advanced cutting technology, automatic error compensation, and user-friendly design, this machine is a crucial tool for manufacturers looking to improve production efficiency, reduce material waste, and ensure high-quality results in sound insulation panel production.

Post time: Feb-21-2025